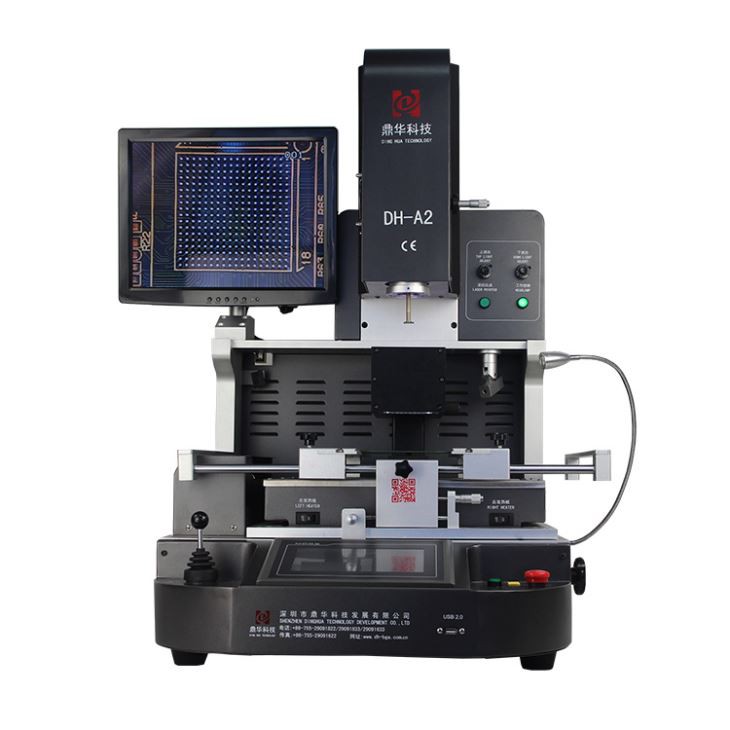

BGA Rework Machine Automatic

DH-A2 Automatic BGA Rework Machine with 3 independent heating areas and optic alignment system. Available in stock. Welcome to order.

Description/kawalan

BGA Rework Machine Automatic

BGA (Ball Grid Array) Rework Machine is a device used in electronics manufacturing to repair or replace

components on a printed circuit board (PCB) that has BGA packages. An automatic BGA rework machine

operates through a pre-programmed process, which ensures consistent and accurate results. The machine

typically uses a combination of heat and pressure to remove and replace the BGA components. The use of

an automatic BGA rework machine can help to improve the efficiency, accuracy, and reliability of the repair

process, compared to manual rework.

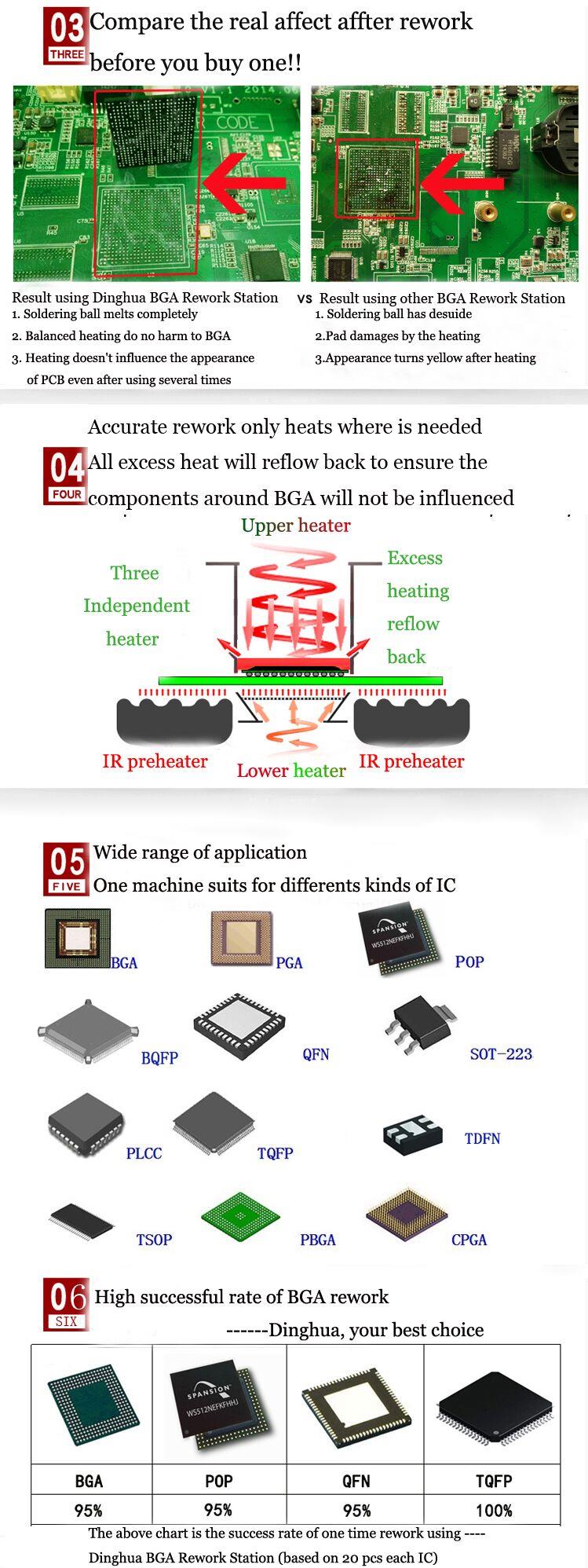

1.Application Of BGA Rework Machine Automatic

Solder, reball, desoldering different kind of chips: BGA,PGA,POP,BQFP,QFN,SOT223,PLCC,TQFP,TDFN,TSOP,

PBGA,CPGA,LED chip.

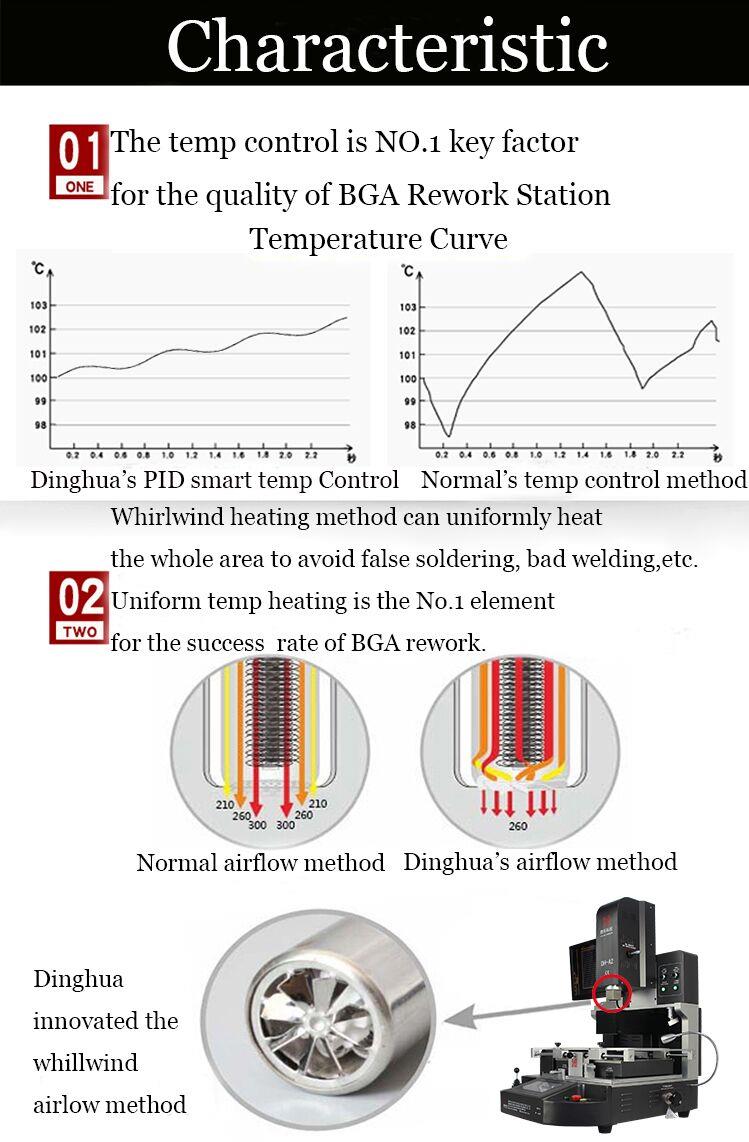

2.Product Features of laser position BGA Rework Machine Automatic

3.Specification of laser positioning BGA Rework Machine Automatic

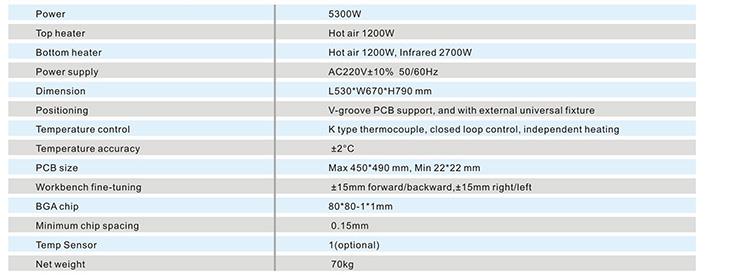

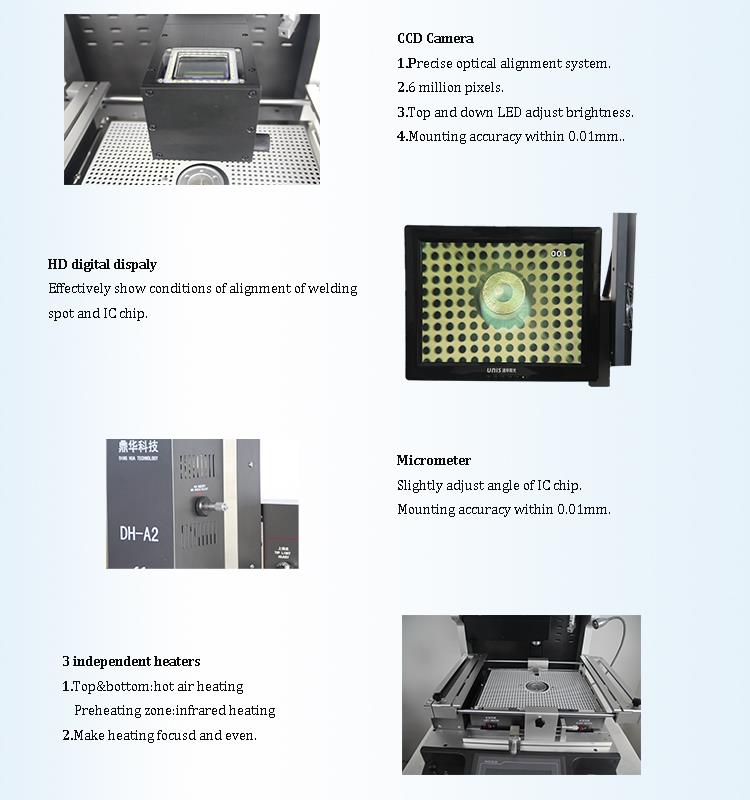

4.Details of Hot Air BGA Rework Machine Automatic

5.Why Choose Our Infrared BGA Rework Machine Automatic?

6.Certificate of Optical Alignment BGA Rework Machine Automatic

UL, E-MARK, CCC, FCC, CE ROHS certificates. Meanwhile, to improve and perfect the quality system,

Dinghua has passed ISO, GMP, FCCA, C-TPAT on-site audit certification.

7.Packing & Shipment of CCD Camera BGA Rework Machine Automatic

8.Shipment for BGA Rework Machine Automatic Split Vision

DHL/TNT/FEDEX. If you want other shipping term, please tell us. We will support you.

9. Terms of Payment

Bank transfer, Western Union, Credit Card.

Please tell us if you need other support.

10. Operation guide for Automatic BGA Rework Machine

11. Contact us for BGA Rework Machine Automatic

Email: john@dh-kc.com

MOB/WhatsApp/Wechat: +8615768114827

Click the link to add my WhatsApp:

https://api.whatsapp.com/send?phone=8615768114827

12. Related knowledge of BGA Rework Machine Automatic

What is the process of corrosion of pcb circuit board?

Pcb circuit boards are widely used in electronics, computers, electrical appliances, mechanical

equipment and other industries. It is the support of components, mainly used to connect comp-

onents to provide electrical, the most common and widely used four-layer and six-layer circuit

boards. According to the industry application, different degrees of pcb board layers can be sel-

ected. Below, let's take a look at the basics of pcb boards and the process of PCB board corros-

ion.

Printed circuit board:

Also known as printed circuit board, printed circuit board, referred to as printed board, English

referred to as PCB (printed circuit board or PWB (printedwiringboard), with insulating board as

the substrate, cut into a certain size, with at least one conductive pattern attached, and cloth Ho-

les (such as component holes, fastening holes, metallized holes, etc.) are used to replace the chas-

sis of electronic components of conventional devices, and to achieve interconnection between el-

ectronic components. Since the plates are made by electronic printing, Therefore, it is called "prin-

ting" circuit board. It is not clear that it is customary to call "printed circuit board" as "printed circ-

uit" because there is no "printing component" on the printed board and only wiring.

The PCB board is an important electronic component and a support for electronic components. Aut-

omatic soldering machines provide technical support for the soldering of PCB boards, and the devel-

opment of electronic components has progressed. However, the problem of corrosion of PBC circuit

boards has been plagued by automatic soldering merchants. Through years of experience, Shenzhen

Dinghua has solved the problem of solving the corrosion of PCB circuit boards.

What is the process of corrosion of the PCB board:

The corrosive liquid is usually prepared by adding ferric chloride and water. The ferric chloride is a kh-

aki solid and is also easy to absorb the moisture in the air, so it should be sealed and stored. When dis-

posing ferric chloride solution, generally use 40% ferric chloride and 60% water, of course, more ferric

chloride, or use warm water (not hot water to prevent paint from falling off) can make the reaction fas-

ter. Note that ferric chloride has a certain degree of corrosiveness. Try not to touch the skin and cloth-

es. The reaction container is made of cheap plastic pots, and the circuit board is placed.

Corrosion of the PCB circuit board from the edge, when the unpainted copper foil is corroded, the circ-

uit board should be taken out in time to prevent the paint from falling off and corroding the useful circ-

uit. At this time, rinse with water, and scrape off the paint with bamboo and the like (the paint comes ou

t of the liquid and is easier to remove). If it is not easy to scrape, just wash it with hot water. Then dry it

and sand it with sandpaper to reveal a shiny copper foil. A printed circuit board is ready. In order to pre-

serve the results, the polished PCB board is usually coated with a rosin solution to both weld and preve-

nt oxidation.

The above is the corrosion process and basic knowledge of the pcb circuit board, I hope to help everyone.