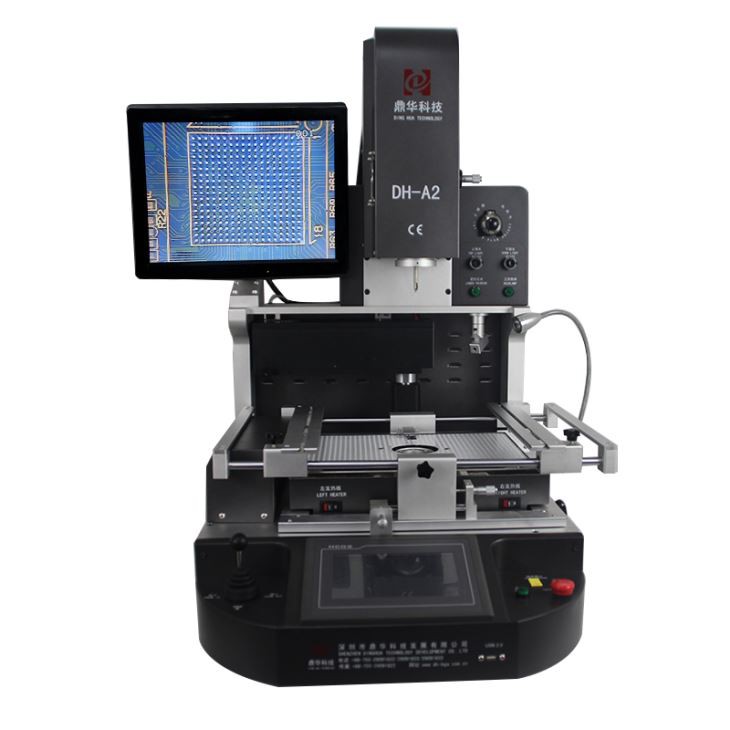

BGA Rework Station Automatic

The DH-A2 BGA Rework Station is a type of automated machine used for repairing or reworking Ball Grid Array (BGA) packages in electronics. This specific machine is designed for removing and replacing BGAs on printed circuit boards (PCBs) in a fast, efficient, and accurate manner. The DH-A2 is equipped with infrared heating and precision alignment mechanisms to ensure that the BGAs are properly placed and soldered onto the board. The machine's automation helps reduce the chance of human error and make the rework process quicker. Overall, the DH-A2 BGA Rework Station is a valuable tool for electronics repair and assembly, particularly for after-sales services.

Description/kawalan

DH-A2 BGA rework station automatic

The term "BGA Rework Station Automatic" refers to an automated machine that is used for reworking or

repairing Ball Grid Array (BGA) packages. BGA packages are widely used in electronics, particularly in the

assembly of printed circuit boards (PCBs). BGA Rework Station Automatic machines are designed to handle

the delicate and precise process of removing and replacing BGAs on PCBs without damaging the components

or the board. These machines typically use infrared heating and precision alignment mechanisms to ensure

that the BGAs are properly placed and soldered onto the board. The automation aspect of the machine makes

the process faster, more efficient, and less prone to errors compared to manual rework.

Functional components of BGA rework station automatic

1.Application Of laser positioning DHA2 BGA Rework Station

Work with all kinds of motherboards or PCBA.

Solder, reball, desoldering different kind of chips: BGA,PGA,POP,BQFP,QFN,SOT223,PLCC,TQFP,TDFN,TSOP,

PBGA,CPGA,LED chip.

2.Product Features of Optical Alignment DHA2 BGA Rework Station

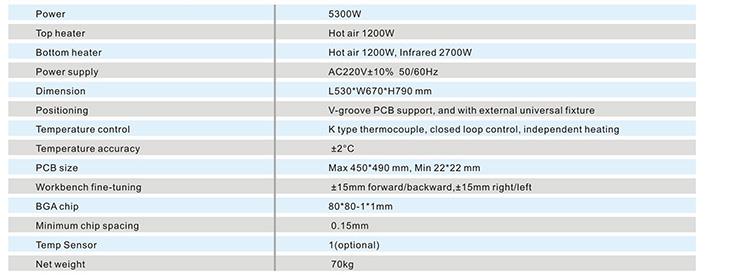

3.Specification of DHA2 BGA Rework Station

4.Details of Laser Positioning DHA2 BGA Rework Station

5.Why Choose Our DHA2 BGA Rework Station Split Vision?

1). Precision and accuracy: The split vision feature provides precise alignment of the BGA on the printed circuit

board (PCB) during the rework process, ensuring a successful outcome.

2).Easy to use: The DHA2 BGA Rework Station Split Vision is designed to be user-friendly and intuitive to operate,

making it ideal for technicians of all skill levels.

3).Automated process: The automation of the rework process eliminates the risk of human error and makes the

process more efficient and consistent.

4).High-quality results: The machine's precision alignment, infrared heating, and hot air rework capabilities result in

high-quality and reliable BGA connections.

5).Cost-effective: Investing in a BGA Rework Station can save time and money in the long run, as it reduces the need

for manual rework and increases the efficiency of the process.

6.Certificate of Automatic DHA2 BGA Rework Station

UL, E-MARK, CCC, FCC, CE ROHS certificates. Meanwhile, to improve and perfect the quality system,

Dinghua has passed ISO, GMP, FCCA, C-TPAT on-site audit certification.

7.Packing & Shipment of DHA2 BGA Rework Station with CCD Camera

8.Shipment for Laser DHA2 BGA Rework Station with Optical alignment

DHL/TNT/FEDEX. If you want other shipping term, please tell us. We will support you.

9. Terms of Payment

Bank transfer, Western Union, Credit Card.

Please tell us if you need other support.

10. How DH-A2 BGA Rework Station works?

11. Know-how for using the DH-A2 BGA Rework Station will vary depending on the specific model

and manufacturer, but here is a general outline of the steps involved:

1.) Preparation: Gather all necessary tools and materials, such as a PCB with a BGA that needs to be

reworked, a new BGA, soldering paste, and a soldering iron. Clean the PCB and the new BGA to rem-

ove any contaminants.

2.)Alignment: Align the BGA on the PCB with the machine's precision alignment mechanism, making

sure that it is in the correct position.

3.)Heating: Use the infrared heating mechanism to heat the BGA to the required temperature. This w-

ill help the BGA become more pliable and make it easier to remove.

4.)Removal: Use upper&lowere hot air gun to gently remove the old BGA from the PCB. Be careful not to

damage the PCB or the surrounding components.

5.)Cleaning: Clean the area on the PCB where the new BGA will be placed to remove any residue from

the old BGA.

6. )Placement: Apply soldering paste to the pads on the PCB where the new BGA will be placed. Align the

new BGA with the precision alignment mechanism, and use the hot air gun to reflow the soldering paste

and securely attach the new BGA to the PCB.

7.)Cooling: Allow the new BGA to cool to room temperature after soldering.