Infrared Rework Station Repair BGA SMD

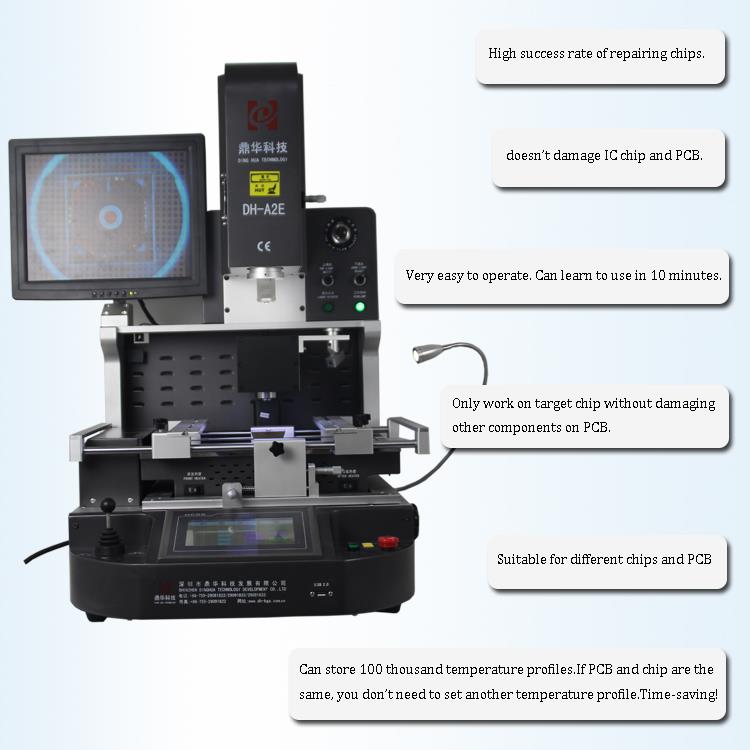

Dinghua DH-A2E Infrared Rework Station Repair BGA SMD machine with high degree of automation and high successful rate of repairing.

Description/kawalan

Automatic Infrared Rework Station Repair BGA SMD Machine

Video of BGA rework machine DH-A2E:

1.Product Features of Automatic Infrared Rework Station Repair BGA SMD Machine

•High successful rate of chip-level repairing. Desoldering, mounting and soldering process is automatic.

• Convenient alignment.

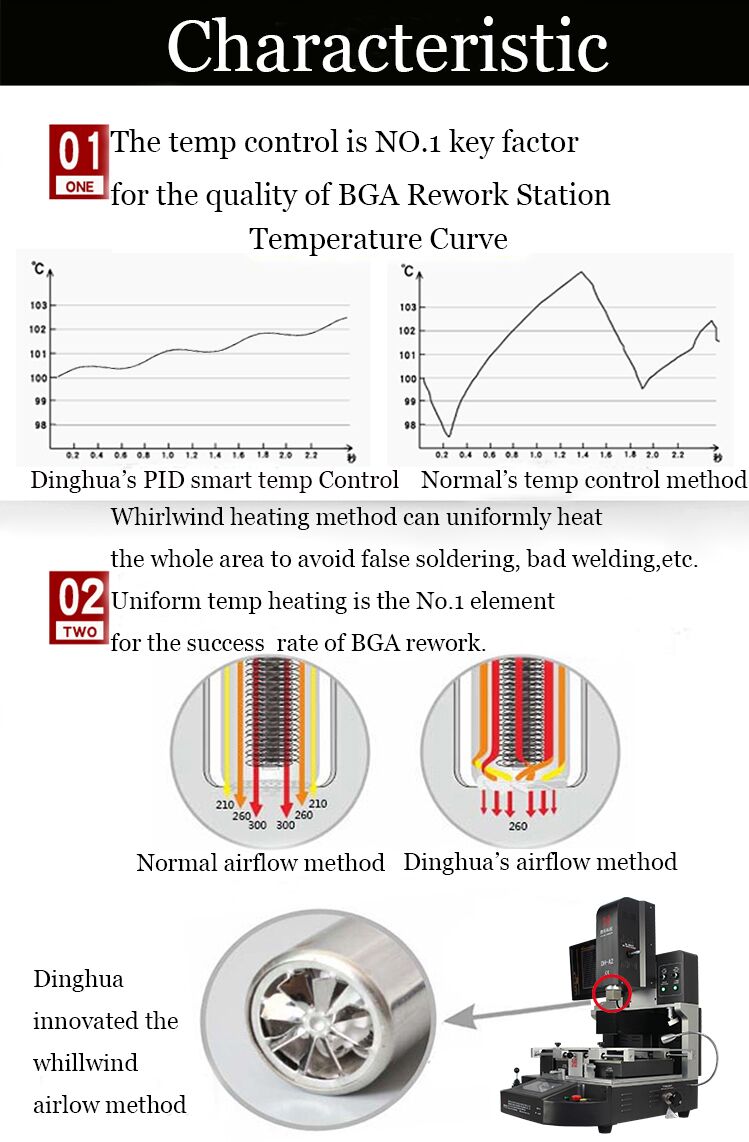

•Three independent temperature heatings + PID self-setting adjusted, temperature accuracy will be on ±1°C

•Built-in vacuum pump, pick up and place BGA chips.

•Automatic cooling functions.

2.Specification of Automated Infrared Rework Station Repair BGA SMD Machine

3.Details of Hot Air Automatic Infrared Rework Station Repair BGA SMD Machine

4.Why Choose Our Automatic Infrared Rework Station Repair BGA SMD Machine?

5.Certificate of Optical alignment automatic Infrared Rework Station Repair BGA SMD machine

6. Packing list of Optics align CCD Camera Infrared Rework Station Repair BGA SMD machine

7. Shipment of Automatic Infrared Rework Station Repair BGA SMD machine Split Vision

We ship the machine via DHL/TNT/UPS/FEDEX, which is fast and safe. If you prefer other terms

of shipment, please feel free to tell us.

8. Contact us for an instant reply and the best price.

Email: john@dh-kc.com

MOB/WhatsApp/Wechat: +86 15768114827

Click the link to add my WhatsApp:

https://api.whatsapp.com/send?phone=8615768114827

9.Related knowledge of Automatic Infrared Rework Station Repair BGA SMD

Rework and repair are very important aspects of electronic packaging technologies. A body of

knowledge (BOK) or research survey of rework equipment, rework methods, and rework contr-

act manufacturers has been provided herein on printed wiring assemblies, ball grid arrays (BGAs),

flip-chip packages, 0201 technologies, polymer based component rework, flip-chip technologies,

plated through hole technologies, micro surface mount device component technologies, quad flat

pack technologies, lead free solder alloys, etc. Rework related issues are similar for all packaging

technologies, but they differ in the materials properties that are employed. Basically, one needs

suitable equipment and experienced technical people to carry out rework tasks. Rework related

issues with reference to workmanship rework standards for surface mount technology (SMT) have

also been documented. Equipment requirements for rework, training courses for rework, various

commercially developed technologies employed for rework of advanced packaging technologies

have been identified and are presented in tabular form in Appendix A.