Infrared Touch Screen Bga Reballing Station

Infrared touch screen BGA reballing station The BGA rework station DH-B2 with multiple features, such as Top air flow, blue-tooth speaker, carbon fiber heating tubes, glass-shield and double shadowless lights etc. Very popular for those people who work on personal repair shop, personal repair...

Description/kawalan

Infrared touch screen BGA reballing station

The BGA rework station DH-B2 with multiple features, such as Top air flow, blue-tooth speaker,

carbon fiber heating tubes, glass-shield and double shadowless lights etc. Very popular for those

people who work on personal repair shop, personal repair hobby and individual workshop etc.

The product parameters of infrared touch screen BGA reballing station

Total Power | 5100W |

Top heater | 1200W(HR) |

Bottom heater | The 2nd area: 1200W(HR), the 3rd 2700W (IR :large preheating area for almost all of PCB/MB) |

Top air flow adjusting | For micro chip repaired |

Blue-tooth speaker | Can connect any cellphone for music/broadcast listening |

IR preheating area | Carbon fiber heating tubes and glass-shield |

Power supply | AC110~220V±10%50/60Hz |

Dimensions | L500×W600×H700 mm |

Positioning | “V” groove, PCB tables adjusting its in X direction, and jig/fixtures |

Temperature control | K Sensor Closed loop |

Temp accuracy | ±2 degree |

PCB size | Max 500×400 mm, Min 22×22 mm |

BGA chip | 2X2-80X80mm |

Minimum chip spacing | 0.15mm |

External Temperature Sensor | 4, optional |

Net weight | 45kg |

The product details of infrared touch screen BGA reballing station

Double shadowless lights, imported from Taiwan region, 5W as per one, bright and focusing

on PCB/MB, no matter where you are standing, there is no shadow on PCN, so that the com-

ponents can be observing clearly.

4 temp sensor ( thermocouple ), for real-time temperature tested if needed, 4 ones can be tested

at same time so that technician can calibrate relevant temperate if any offset.

Top air flow adjusting, there is 10-class for your adjusting, usually , for the chip size more than

20*20mm, you can switch it to 5-class or more , on the other hand, it will be switched to less t-

han 10-class, such as, if the chip is 10*10mm, it will be rotated to 5-class.

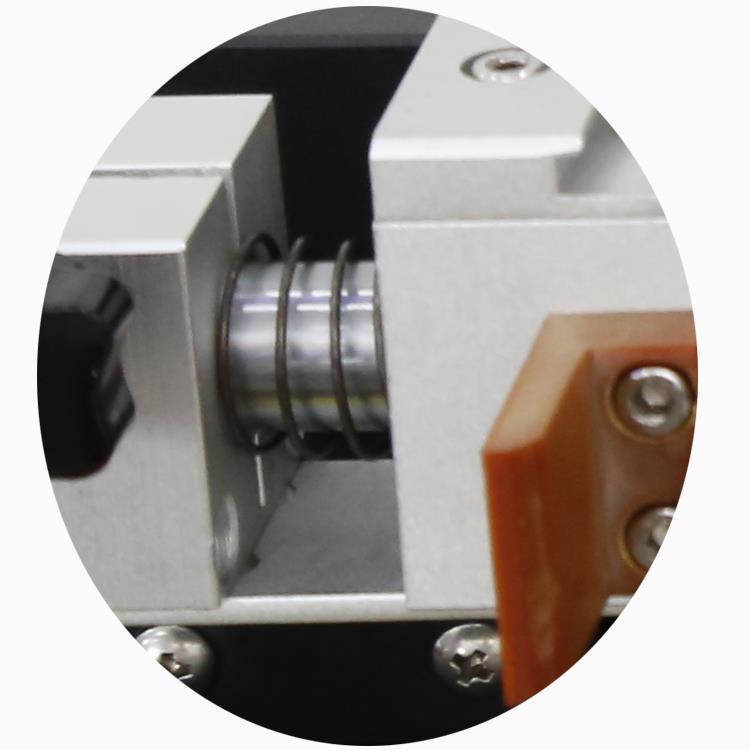

Spring than installed on working bench, when PCB/MB is being heated, it will work for

PCB protected , so make the PCB best protection.

Blue-tooth speaker, which can connect any mobile phone for music enjoying or broadcast

listening etc. Working while listening for much better and higher successful rework rate.

Carbon fiber heating tubes and covered by glass-shield which can prevent any small compo-

nents or dust from dropping inside, and the red light of tubes is easy to be absorbed by PCB

and longer&stable using life.

Also, there are 4 switches for the relevant tubes respectively, if smaller PCB repaired, 1 or 2

of them can be turned off for saving power and less so that there is less greenhouse gases on

the earth.

The product quality of infrared touch screen BGA reballing station.

All of products have CE passed, and awarded High-tech industry qualification certificate, Inde-

pendent intellectual property certificate and Tax certificate by our central office or regional d-

epartment.

Factory outside located in where it is closed to mountain with fresh air, and not far away from

subway station(5 minutes taking car) and bus station(5 minutes on feet), convenient for custo

mers visiting.

This is part of our factory for BGA rework station, have others for screw locking machine,

soldering station and glue dispensing machine etc.

FAQ: of this machine DH-B2 infrared touch screen BGA reballing station

1. Q: Can I design(change) a little something on the machine?

A: Usually, It’s OK, but if massive quantity, that would be cost-effective.

2. Q:What are the steps of BGA repair?

A: First, remove the components;Next, remove the residual solder.Once you have removed

all the excess solder After the excess solder has been removed and the BGA has been reba

lled, finally, soldering.

3. Q: What does your factory rank in China?

A: We are the number one in this industry in China.

4. Q: Can you accept OEM? If yes, how many is the minimum quantity?

A: Yes, it depends on when you are going to purchase. Usually more than

50 set.